Description

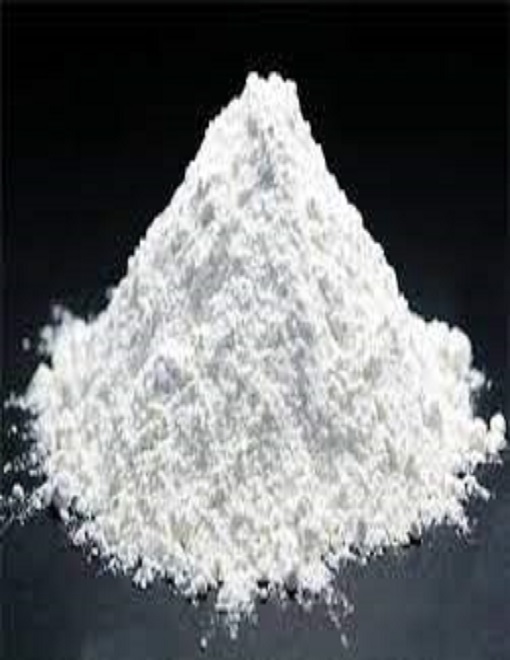

Calcium carbonate is a chemical compound with the formula CaCO3. It is one of the most abundant minerals found in the Earth’s crust and is widely recognized for its diverse applications in various industries.

Calcium carbonate is a white, odorless powder with a crystalline structure. Its physical properties vary depending on the form and size of the particles.

Precipitated calcium carbonate (PCC) consists of fine particles, while ground calcium carbonate (GCC) is composed of larger particles. The compound is relatively insoluble in water but dissolves easily in acids, making it reactive under certain conditions.

Precipitated Calcium Carbonate (PCC) is synthesized through the reaction of calcium hydroxide and carbon dioxide. This process creates ultrafine particles with controlled sizes and shapes, making it suitable for various applications. Ground Calcium Carbonate (GCC) is obtained by mechanically grinding natural limestone or marble.

The most abundant natural source of calcium carbonate is limestone, a sedimentary rock primarily composed of calcium carbonate. Limestone forms over time through the accumulation of marine organisms’ skeletal remains and precipitation of calcium carbonate from water.

Another natural source of calcium carbonate is chalk, which is formed from the remains of microscopic marine organisms known as coccolithophores.

Calcium carbonate serves as a crucial component in cement production, acting as a filler and controlling the setting time of concrete. Crushed limestone is used as an aggregate in road construction, building foundations, and as a base material for asphalt and concrete.

Calcium carbonate is widely employed as a filler in the paper and pulp industry to improve paper opacity, brightness, and bulk. It also enhances the printability and smoothness of paper surfaces.

Calcium carbonate is extensively used as a filler in plastic and polymer products to enhance their mechanical properties, reduce costs, and improve dimensional stability.

Calcium carbonate is a common ingredient in calcium supplements due to its high calcium content and bioavailability. It helps prevent calcium deficiency-related health issues, such as osteoporosis. Calcium carbonate acts as an effective antacid to relieve symptoms of acid indigestion and heartburn.

Calcium carbonate is approved as a food additive (E170) and is used as a calcium source, pH regulator, anti-caking agent, and stabilizer in various food and beverage products.

Calcium carbonate is utilized in flue gas desulfurization processes to remove sulfur dioxide emissions from power plants and industrial facilities. It can be employed as a pH regulator and to enhance the removal of impurities in water treatment systems.

The global calcium carbonate market reached a value of USD 19.44 billion in 2021. The market is expected to grow at a compound annual growth rate (CAGR) of four point two percent (4.2%) during the period 2023-2028.

The majority of calcium carbonate’s applications are in agriculture. Limestone’s primary constituent is calcium carbonate.

This mineral is extensively utilized to maintain a healthy pH balance in the soil and supply calcium to plants for optimum nutrition. It aids in absorbing water from the environment, keeping the soil moist and pliable and promoting greater plant and agricultural growth. The growing demand for calcium carbonate in agriculture is anticipated to fuel market expansion.

The need for calcium carbonate in the paper sector has been very profitable. Both ground calcium carbonate and precipitated calcium carbonate are finding favour in the paper-making process. Precipitated calcium carbonate is a crucial component in the production of paper due to its superior operational flexibility.

The printing surfaces of the paper have improved with the use of precipitated calcium carbonate in the paper industry. Thus, the growing demand for both ground and precipitated calcium carbonate in the paper industry is anticipated to propel the calcium carbonate market’s growth rate.

Other significant factors that are anticipated to increase the demand for calcium carbonate in the market during the forecast period include the favourable features of calcium carbonate and expansion in the manufacture of polymers and plastics.

Limestone is widespread in the sedimentary basins of Nigeria and prominent reserve has been proved to exist all over the country.

The marble and dolomite deposits in Nigeria are often associated with the meta-sediments such as schist, amphibolites complex and metal-conglomerates. They are also used as flux in steel making.

Limestone deposits in different parts of Nigeria are in excess of two billion (2,000,000,000) metric tons and this report seeks to examine the financial viability or otherwise of establishing limestone/ marble milling plant in Nigeria

The milled limestone/marble is suitable for the production of cement, fluxing material, powder filler for paper, rubber, paint, glass, ceramics, pharmaceutical, quicklime, hydrated lime and calcium carbonate.

The demand for milled limestone/marble is quite high in Nigeria and the raw material is also available in commercial quantity.

Reviews

There are no reviews yet.